In a Passive House not everything is isolation. And it is that in addition to the concepts of insulation, sealing, absence of thermal bridges… mechanical ventilation is essential. And to comply with the Passive standard and for our Passive House to be certified, the mechanical ventilation must be solved by means of a Passive heat recovery unit.

Which makes perfect sense. In the end we have achieved a very isolated and airtight house, so air losses are very limited, so we will have to control and manage the ventilation of the house. And for this we must do it the right way by calculating flows, in an energy efficient way, and through filters to improve the quality of the air inside the house.

What is a heat recovery unit?

Within the different ventilation systems for passive houses, the heat recovery unit is the most widespread element and the one that provides the best solution today. The Passive heat recuperator is the passive air conditioning system that renews the stale air in our home by pumping new air from outside. After passing through some filters that ensure that the air that enters the house is free of allergens, mites… improving the interior quality of the home.

Or what is the same, maintaining the optimal conditions of our Passive House in terms of health and comfort.

How does a heat recovery unit work?

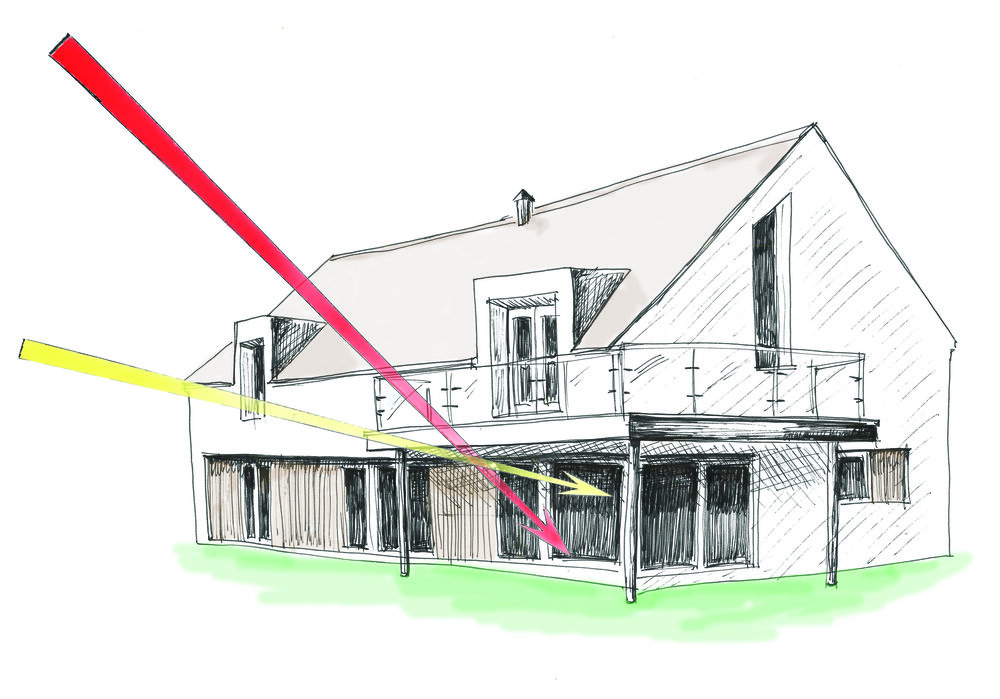

The operation is very easy to understand when we think of a traditional home in which the only way to ventilate is through the windows. Let’s imagine that we are in winter, with 5 degrees outside the house. If we want to ventilate to expel the stale air (more concentration of CO2 and less of oxygen, odours.) we will have to open the windows for a while.

This will necessarily allow cold to enter the interior of the dwelling (which will mean that the heating will have to be activated with greater force). And at the same time an air that may contain more dust, allergens… depending on where the home is located. If it is a house within a plot with land, lawn, orchard… or we are in the center of a city, the air that enters our home may contain dust, pollution…

In a Passive House with a heat recovery unit, if we open the windows (of course the windows can be opened in a passive) the same thing will happen. But be careful, even if you can, it is not necessary to do it to ventilate. And therein lies the main question. To ventilate the house we will use the heat recuperator that when it introduces new air into our house it does so after air conditioning it. The air no longer enters at 5º but instead, taking advantage of the temperature of the air it expels, it preheats it, which improves energy efficiency. And at the same time, through the filters, it guarantees that the air in our home is free of unwanted particles.

Function of the heat recovery unit in Passive homes

The main function of the heat recovery unit in a Passive House, which is therefore highly sealed, is to mechanically renew the interior air in an efficient and filtered way.

This allows us to have better air quality and therefore healthiness and interior comfort. And at the same time save on air conditioning (heating or cooling) of that same renewed air.

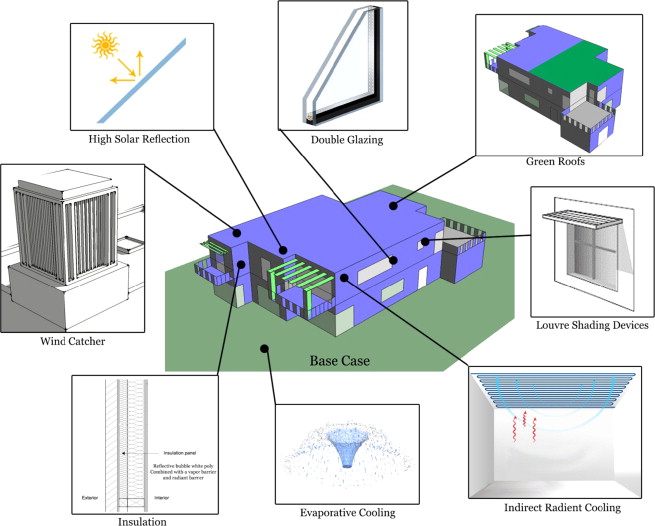

Characteristics of a heat recovery unit for use in Passive Houses

A Passive heat recovery unit must meet a series of characteristics in order to be a Passive certified element.

- It must have a minimum efficiency of 75%. This influences the performance of the supply air pre-conditioning depending on how it uses the exhaust air.

- The power is also limited to ensure low energy consumption and economical ventilation. The power of our recuperator must not exceed 0.45 Wh/m3.

- Precisely to ensure that the air that enters our home should not be heated excessively and therefore be an efficient system, the supply temperature is limited. That is why it should not be less than 16.5º C when outside it is not less than -10º C.

- To ensure the correct functioning of the system, unwanted air leaks must not exceed 3%. In this way, the air tightness of the house is guaranteed.

On the other hand, it is important to assess the efficiency of the system based on the air flow as well as the difference between the outside and inside air temperature. And it is that the higher the flow, the lower the efficiency of the heat recovery unit. Just as its efficiency will be greater, the greater the temperature difference between the interior and exterior air.

Types of heat recovery

There are several alternatives.

- Heat recovery unit with cross flow exchanger

In this case, there is a perpendicular crossing of the air currents between supply and extraction inside the heat recovery unit. Efficiencies of 50% to 85% are obtained.

- Heat recovery unit with parallel flow exchanger

Here the air circulation between impulsion and extraction goes in parallel and in countercurrent inside the heat recovery unit. In this way the exchange surfaces increases and therefore the efficiency of the system, being able to reach 90% or 95%.

- Heat recovery unit with rotary flow exchanger

This system differs from the previous ones in that it uses a rotor that works like a fan thanks to a low consumption electric motor. It reaches approximate efficiencies of 70% to 85%.

Enthalpy heat recovery

This type of heat recuperators deserves a separate category. And it is that in this case the exchanger is enthalpic to recover both the sensible and the latent energy of the recuperator. Or what is the same, the heat recuperator takes advantage not only of the temperature but also of the humidity in the recovery of energy from the extraction air.

This type of heat recuperators is based on the same principle as sensible energy recuperators but adding the humidity variable. This is especially interesting when there is a large difference in humidity values between the interior and exterior of the house. Either due to climatic conditions abroad (due to excess or deficiency) whose most common case is when it is a coastal area. Either because of the conditions inside, determined mainly by use, as is the case with indoor pools, gyms…

Which recuperator has higher performance? The enthalpic or the sensitive one?

A priori, energy recovery in sensitive equipment is greater than that of enthalpy recuperators. Therefore, an enthalpy recuperator should only be used in cases where it is needed due to the difference in humidity between the interior and exterior of the home.

Installation of a heat recovery unit

Regarding the type of installation, there are heat recovery models that are installed in a horizontal position and in a vertical position, according to its dimensioning based on your needs. This choice also supposes an important advantage of space according to the distribution requirements.

In any case, the installation of a heat recovery unit, as well as any Passive element, must be carried out by a specialized and certified company for the handling and use of this type of equipment. It is fundamental in a heat recovery unit, not only the sizing of the machine and ducts according to the house and demand, but also its calibration and start-up once it has been installed. This will ensure perfect operation during the useful life of the house. And as we have already said, this will result in greater energy efficiency and comfort.